คำอธิบาย

Aggregation of Cutting-Edge Functions

Revolutionary Technology Provides Full Control

Ultra-high-speed Ultra-high-response

data sampling crosshead control

10kHz × 1kHz

Equipped with Multi Processors and Multi Engines, Providing Ultrafast Data Acquisition and High Response Control

Shimadzu’s proprietary control box is equipped with two processors and three engine units. It provides 1 kHz high response crosshead control and 10 kHz high-speed data sampling through high-level simultaneous parallel processing, based on a meticulous timing design, and the allotment of various communications, measurement, and control functions across multiple devices.

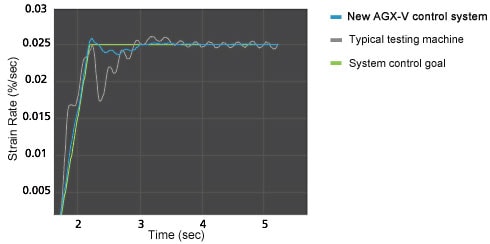

Leave Strain Rate Control to the Machine by Utilizing New Autotuning

High-accuracy control is maintained under noisy, highly disturbed conditions, something that was hard to provide with conventional autotuning.

This high-level autotuning is achieved by using not only feedback measurement values but all measurement values in the calculations for real-time updates of the control model.

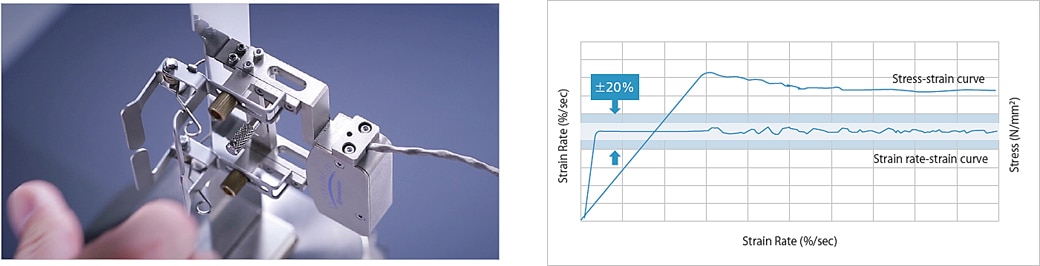

[Steel and Nonferrous Metal Testing]

Strain rate control, in which the rate of deformation measured by an extensometer is controlled to be constant, requires highly accurate control to follow rapid changes in material behavior.

Metal Tensile Test Standard: ISO 6892(JIS Z 2241) specifies that the allowable range of increase in strain to the yield point is ± 20% or less. The strain rate control specified in ISO 6892(JIS Z 2241) is possible*1 to achieve with the AGX-V2 for many materials.

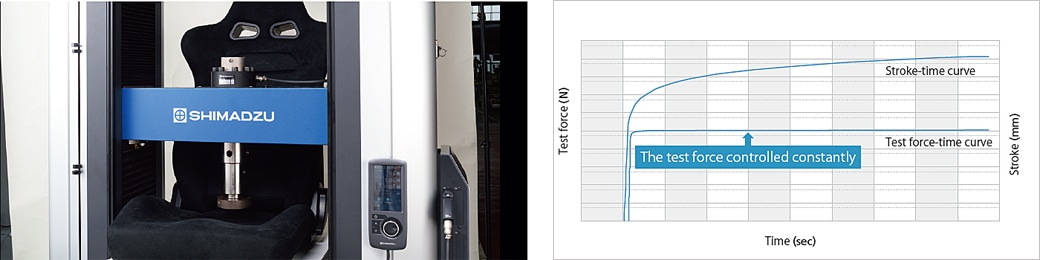

[Practical Simulation Testing]

To maintain engine mounts and other rubber materials at a constant test force, it is necessary to gradually change the retention position to suit the characteristics of the test sample. In order to maintain the test force at a constant value, high control stability is required, with high control responsiveness and no vibrations generated due to excessive response.*2

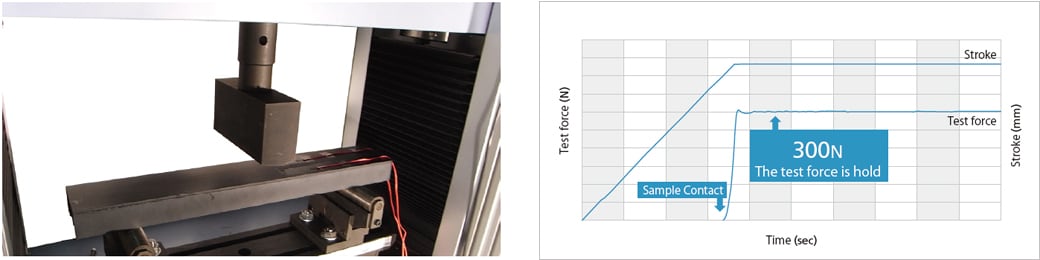

[Free Running Compression Testing]

Stable control is achieved even in free running compression tests. In these tests, the compression indenter or bending punch is allowed to run free until it makes contact with the sample, at which point the load is increased up to a set test force.

The overshoot of the target value is reduced, even in free running compression tests of highly rigid materials, resulting in high-accuracy test force retention.*2

*1 The graph is an example. The control accuracy may vary depen ding on the material properties and the surrounding environment . It does not guarantee accuracy.

*2 The graph is an example. The state of control can vary depen ding on the material properties and the surrounding environment.

Wider Range, More Detail, More Variety

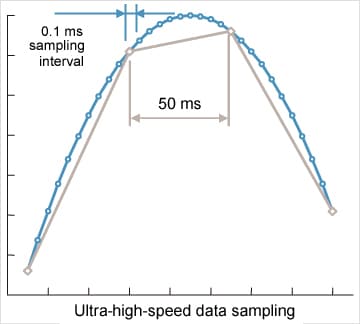

Ultra-high-speed data sampling

10kHz

Captures Instantaneous Changes

The ultra-high-speed sampling function has progressed up to a sampling rate of 10 kHz (0.1ms). Sudden and tiny changes, such as when brittle materials break, can now be assessed.

Guaranteed test force range

1/2000

Reduces the Frequency of Load Cell Replacement

The guaranteed test force accuracy range has been enlarged to 1/2000 for an even wider range of data reliability. Even data from the very beginning of the test force application can be analyzed with confidence. Tests that previously required multiple load cell replacements to suit the test force are now supported by a single load cell, cutting back on replacement procedures and calibration expenses.

Maximum number of sensor inputs

20ch

All the Data Are Synchronized and Acquired with High Accuracy A Data Logger is Not Required

The external input ports can be expanded to 20 channels. Analog input units and counter units can be selected, making it easy to acquire more data without a data logger. The load cell, extensometer, and external input ports are synchronized, and all channels are sampled simultaneously, improving the simultaneity of the data. This further improves the accuracy and reliability of the elastic modulus and other data calculated using two or more measurement values

Testing Machine Main Unit

Load Frame

Frame Design Provides High Rigidity and High-Level Alignment

The newly designed guide column*1 is equipped with a support ring*1 that maintains a right angle with the table surface. As a result, measurement repeatability has been improved in tests of highly rigid materials and highly brittle materials, prone to the impact of frame rigidity or alignment, enabling stable testing.

Voice Operation Device

XV-Talk™

New Operability with Voice

The AGX-V2 responds to the operator’s voice.

The AGX-V2 operates in response to key phrases spoken by the operator. This frees the operator from frequently used buttons, such as “Start Test” and “Return.”*2*3